Our in-house engineering and data-driven approach deliver reliability and repeatability at scale, supporting critical fleet and OEM needs.

Cost efficient solutions

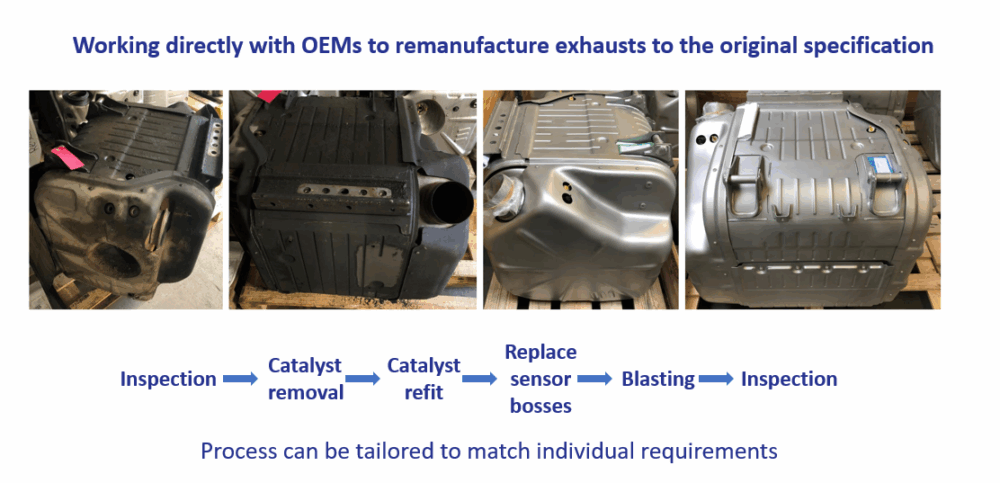

Reman from Ceramex enables exhaust aftertreatment system components to be remanufactured to ‘as-new’ quality. As well as to delivering cost saving efficiencies, it also supports your Environmental Social Governance (ESG) framework and will help the reduction of your business’s carbon footprint and environmental impact.

Utilising our reman expertise means you can expect consistent, high performance of your exhaust aftertreatment components and be assured of little or no variance in performance.

Quality assured procedures

Through our sophisticated reman processes we can take your worn out or failed component or piece of equipment and makes it ‘as new’. Our reman procedures have been established for several years and offer a market-leading alternative to purchasing a new exhaust aftertreatment systems (EATS) or components thereof, including Euro VI diesel particulate filters (DPF).

We deliver solutions for major brands in on- and off-road industries, including visual inspections, leak testing, thread inspections and disassembly. We repair and replace DPF, diesel oxidation catalysts (DOC) and bosses.

We can also complete unit cleaning by bead blasting and will reassemble and ship globally from our Slovakia and UK facilities, to suit your requirements. These local solutions will maximise performance of your exhaust aftertreatment components, cost effectively.

Copyright 2025 Eminox Registered in the UK Registration NO. 01349209 CRT and SCRT are registered trademarks of Johnson Matthey plc.